World's Leading Provider of Used Machinery

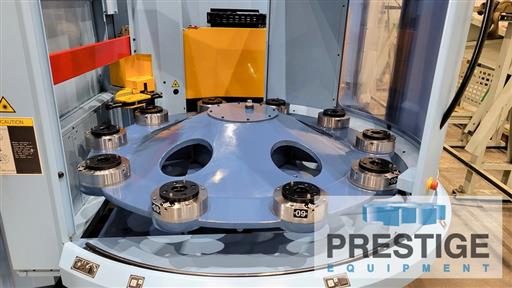

Matsuura MX-330 5-Axis CNC Vertical Machining Center

Model:

MX-330

Age:

2023

Ref#:

43944

Prestige Equipment is the world's leading provider of Matsuura MX-330 5-Axis CNC Vertical Machining Center & machine tools & fabricating equipment. Take a look at our wide selection of new and used CNC Vertical Machining Centers (VMC) for sale.

Product Specifications

Features:

✓

Matsuura G-TECH 31iB CNC Control with 381 MM Touch Screen

✓

Spindle Load Monitoring Function

✓

20,000 RPM High Speed CAT #40 Oil-Air Lubricated Spindle

✓

10 Station Pallet System

✓

Renishaw OMP-400 Spindle Probe

✓

Renishaw NC-4 Laser Tool Setter Probe

✓

1,000 PSI Coolant Through Spindle Preparation

✓

90 Station Automatic Tool Changer

Product Specifications

CAPACITY:

X-Axis Stroke

435 MM

Y-Axis Stroke

465 MM

Z-Axis Stroke

560 MM

A-Axis Rotation

-125/+10 Deg.

C-Axis Rotation

360 Deg.

Working Surface

250 MM

Loading Capacity

80 KG .

Maximum Workpiece Size

330 MM x 320 MM

Spindle Drive

11 KW / 15 KW

Spindle Speeds, Max.

20,000 RPM

Spindle Taper

CAT #40

Rapids, X/Y/Z

40000 MM/MIN

Feed Rate X/Y/Z

40001 MM/MIN

Approximate Weight w/ Pallet System

9752 KG .

Equipped With:

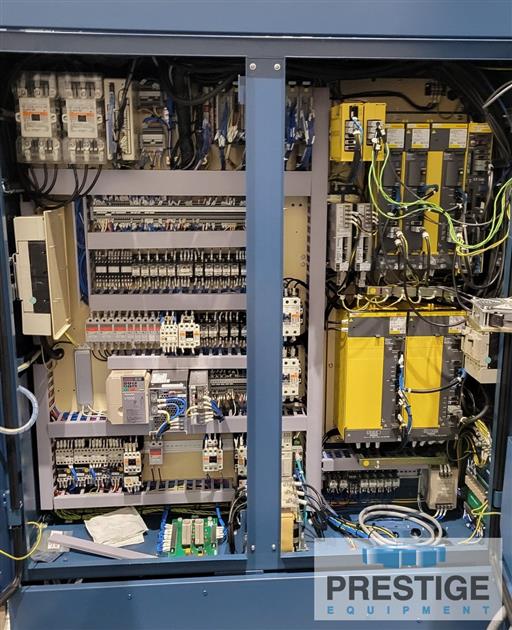

Matsuura G-TECH 31iB CNC Control with 381 MM Touch Screen

Advanced Tap Function/Intelligent Precision Control Function

Spindle Load Monitoring Function

MIMS (Matsuura Intelligent Meister System)

20,000 RPM High Speed CAT #40 Oil-Air Lubricated Spindle

10 Station Pallet System

Heidenhain Scale Feedback for X,Y,Z Axes

Scale Feedback on A and C Axis

Renishaw OMP-400 Spindle Probe

Renishaw NC-4 Laser Tool Setter Probe

1,000 PSI Coolant Through Spindle Preparation

Air Blow for Chip Swarf Removal

Environmental Thermal Displacement Compensation

Air Driven Rotary Wiper on Operator Window

90 Station Automatic Tool Changer

MB-1200 Mist Collector

93 Gallon Coolant Tank

Internal Spiral Chip Augers

Z-Axis Thermal Displacement Compensation System

Spindle Oil Cooler with Overload Protection

Auto Grease Supply Unit For Feed Axes

Chip Flush/Flow

Mosnic RD-3C Chip Conveyor with Drum Filter (Filters Chips Down to 50 Microns)

Features:

✓

Matsuura G-TECH 31iB CNC Control with 381 MM Touch Screen

✓

Spindle Load Monitoring Function

✓

20,000 RPM High Speed CAT #40 Oil-Air Lubricated Spindle

✓

10 Station Pallet System

✓

Renishaw OMP-400 Spindle Probe

✓

Renishaw NC-4 Laser Tool Setter Probe

✓

1,000 PSI Coolant Through Spindle Preparation

✓

90 Station Automatic Tool Changer

Request a Quote Today

Enter your email address for detailed product information.

OR Contact Us at 631-249-5566

[email protected]

Get Financing

One Click Financing. Learn more here.

One Click Financing. Learn more here.

Auctions & Liquidations

Looking for a great deal? Click here.

Looking for a great deal? Click here.