Worldwide Industrial Auctions & Liquidations

Online Auction

Surplus to the Continuing Operations of a World Renowned CNC Manufacturing Facility

Featuring: (19) Gear Machines Including CNC Gear Shapers, Gear Grinders, Gear Hones, Gear Washers, & Gear Deburring Machines; (12) CNC Vertical Lathes, Turning Centers, and Machining Centers; (12) ABB Robots, (5) CNC & Automatic Hones, (2) Spline Rollers, (18) Presses, PLUS: CNC & Manual Grinders, CMM, Part Washers, Testing/Checking/Assembly Equipment, Conveyor Systems, Filtration Systems, and Much, Much, More!

November 3rd, 2022

1:00 PM ET

Milwaukee, Wisconsin

Sale Information

FEATURED ASSETS:

CNC GEAR SHAPERS:

- Gleason GP-200S CNC Gear Shaping Machine, Fanuc 180i-MB CNC Control, 7.87” Max. Gear Dia., 1.96” Max. Face Width, 2.16” Max. Stroke Length, 1800 SPM, Tailstock, Chip Conveyor, Mist Collector, Chiller, S/N 995703 [2008] VIEW LOT #97

- Lorenz Liebherr LS-153 6-Axis CNC Gear Shaper, GE Fanuc 15M CNC Control, 5.9” Max. Work Dia., 1.732” Max. Face Width Spur Gears, 45 Deg. Max. Helix Angle, 250-1500 SPM, 370 IPM Tool Rotation, 618 IPM Work Rotation, Dual Gripper Ring Type Loader, Tool Clamp, Tailstock, Chip Conveyor, Coolant, Mist Collector, S/N 6072 [2000] VIEW LOT #88

- Lorenz Liebherr LS-82 6-Axis CNC Gear Shaper, Fanuc 180i-MB CNC Control, 7.87” Max. Gear Dia., 1.96” Max. Face Width, 2.16” Max. Stroke Length, 1800 SPM, Tailstock, Chip Conveyor, Mist Collector, Chiller, S/N 995703 [2008] VIEW LOT #140

CNC GEAR GRINDERS:

- (2) Reishauer RZ-362A CNC Gear Grinder, 25.39” Centers, 6.88” Max Face Width / Work Slide Travel, 14.17” Max. Tip Dia., 1.96” Min. Root Dia., 132 Lb. Work Weight, 13.77” Max. Worm Dia., 3.30”-3.97” Worm Width, 10-600 Teeth, DP48-DP3,5 Pitch, 10-40 Deg. Pressure Angle, 45 Deg. Max Helix Angle, Automatic Grinding Worm Infeed & Retraction, 3.54” Max. Shift Travel, Diamond Dresser, Marposs Automatic Grinding Wheel Balancing, Oberlin OPF Coolant Filtration Tank, S/N 73967 [1999]; S/N 73711 [1994] VIEW LOT #148 / VIEW LOT #150

CNC GEAR HONES:

- 2004 Prawema SynchroFine HFSL203 High Performance CNC Gear Hone, 1.57”-6.29” Work Dia., Capacity, 2.16” Max. Teeth Width, 7.87” Max. Shaft Length, Travels: X-41.53, Z-11.81”, Head Swivel Angle: -10/+8 Deg., Diamond Dresser, Part Load Station, Rexroth Indramat BTV 20 System 200 CNC Control, Granite Base, Mist Collector, Oberlin OPF Coolant System, S/N 037 059, [2004] VIEW LOT #165

- (2) Fassler K400 5-Axis CNC Gear Hone, NUM 1060 CNC Control, Travels: X-6.29”, Y-25.6”, A- +30/–90 Deg, 0-500 RPM Honing Stone Spindle Drive, 0-1500 RPM Headstock Spindle Drive, Tailstock, Kistler Force Sensing Measuring System, Coolant & Filtration, Mist Collector VIEW LOT #84 / VIEW LOT #89

CNC GEAR DEBURRING & CHAMFERING MACHINES:

- Wera Profilator RM130 CNC Gear Deburring & Chamfering Machine, GE Fanuc 18i-T CNC Control, 1.96” Max. Workpiece Dia., 2.16” Hole, Workpiece Clamping, 1500 RPM Max. Work/Tool Speed, 500-30,000 Overhead Gantry Loader/Unloader, Tool Monitor, Chip Conveyor, 460V S/N 41081, [2000] VIEW LOT #136

- (2) Wera Profilator RM120 CNC Gear Deburring & Chamfering Machine, Siemens Sinumerik 805T CNC Control, 1.96” Max. Workpiece Dia., 2.16” Hole, Workpiece Clamping, 1500 RPM Max. Work/Tool Speed, Overhead Gantry Loader/Unloader, Tool Monitor, Chip Conveyor, S/N 4097398 & S/N 4097498 [1998] VIEW LOT #131 / VIEW LOT #132

- (2) Samputensili SU-SCT-S CNC Deburring/Chamfering Machine, 0.78”-4.33” Part Dia., 4.13” Max. Gear Tooth, 6.5 HP Spindle, Tailstock, Part Holder, Clamping, Upper and Lower Tool Slides, Indexing System, Allen Bradley PanelView 900, Chip Conveyor, Coolant, S/N 2010 [2000]; S/N 1560 [1994] VIEW LOT #128 / VIEW LOT #135

- (2) Modern Burr-Master BMI-14 Gear Tooth and Spline Deburring and Chamfering Machine, S/N 66324 & S/N 64275 VIEW LOT #82 / VIEW LOT #83

GEAR PARTS WASHER:

- Matrix Pinion Gear Parts Spin-Off Machine, Allen Bradley PanelView 300 Micro Interface, [2005] VIEW LOT #95

- Automated Finishing Model 3164 Automatic Gear Parts Washer, Pneumatic Door, Approx 30″ x 16″ Opening, Motorized Parts Rotator, Wash & Blow Off Cycles, Mist Collector, 5 HP Gusher Pump, Bag Filter Filtration, Oil Skimmer, Watlow Electric Tank Heater, Sump Pump, Allen Bradley PanelView Plus 700 VIEW LOT #129

- Automated Finishing Model 3643 Gear Parts Washer, Pneumatic Door, Approx 30″ x 16″ Opening, Parts Rotator, Wash & Blow Off, Mist Collector, 5 HP Gusher Pump, Bag Filter Filtration, Electric Tank Heater, Sump Pump, Allen Bradley PanelView Plus 700 VIEW LOT #130

- Automated Finishing Model 4280 Gear Parts Washer, Pneumatic Door, Approx 30″ x 16″ Opening, Parts Rotator, Wash & Blow Off, Mist Collector, 5 HP Gusher Pump, Bag Filter Filtration, Electric Tank Heater, Sump Pump, Allen Bradley PanelView Plus 700 VIEW LOT #134

CNC VERTICAL AND HORIZONTAL TURNING CENTERS:

- Okuma & Howa 2SP-V35 Twin Spindle CNC Vertical Turning Center, Fanuc CNC Control, 19.68” Swing, 14.73” Max. Turning Dia., 13.77” Max. Turning Length, 25-2500 RPM Spindle Speed, Twin 12-Station Turrets VIEW LOT #137

- Okuma & Howa V40R CNC Vertical Turning Center, Fanuc 18iTB CNC Control, 15.74” Max. Turning Dia., 12-Station Turret, Chip Conveyor, High Pressure Coolant, S/N 4010 VIEW LOT #62

- Emag Reinecker VSC-250-DDS CNC Vertical Hard Turning / Finish Grinding Center, Siemens Sinumerik CNC Control, 9.84” Max. Chuck Dia., 10.23” Swing, Travels: X-33.46”, Z-7.87”, Y-12.40”, With 12-Station Turret, SMW Autoblok DFR-ABS Chuck, HSP-140S High Speed Grinding Spindle, Marposs Probe, Parts Shuttle, Mist Collector, Chip Conveyor, Coolant, [2003] S/N M762.56845 VIEW LOT #143

- Okuma LFS10-2SP Twin-Spindle CNC Turning Center, OSP-U100L CNC Controls, 15.74” Swing, 4.72” Max. Turning Dia., 3.15” Max. Turning Length, 1.57” Bar Cap., 5.70” Z-Travel, 6,000 RPM, Twin 8-Station Turrets, OGL-3F Overhead Gantry Parts Loader, Chip Conveyor, S/N 0122 VIEW LOT #133

- Cincinnati Avenger 250S CNC Turning Center, Acramatic 850SX CNC Control, 12-Position Turret, Sub-Spindle, Tool Eye, Parts Catcher, Chip Conveyor, Mist Collector, S/N 3650B0597-0012 [1997], with LNS QL Servo S2 Bar Feed S/N 301388. AN# BT4578 VIEW LOT #87

- (2) Mori Seiki SL303A/700 CNC Turning Center, MSG501 CNC Control, Mayfran Consep 2000 Chip Conveyor, High Pressure Coolant, Mist Collector, S/N 871 [2001], LOT 7, AN# BT5964; S/N 87 [2001], LOT 8, AN# BT5965 VIEW LOT #7 / VIEW LOT #8

CNC MACHINING CENTERS:

- Mitsui Seiki HU50A 4-Axis CNC Horizontal Machining Center, Fanuc 15-M CNC Control, Travels: X-28.34″, Y-27.55″, Z-5.6″, Automatic Pallet Changer, (2) 19.7″ x 19.7″ Pallets, 60 ATC, 50-Taper, Chip Conveyor, High Pressure Coolant, Mist Collector VIEW LOT #15

- Mori Seiki MV-40E CNC Vertical Machining Center, MSC-520 CNC Control, Travels: 22.04”, Y-16.14”, Z-18.11”, With 35” x 17.71” Table, 660 Lb. Table Load, 20 ATC, 60-6000 RPM, 40-Taper Spindle, NSK Mega Rotary Indexer with NSK FMDI MDI Control, Coolant, Oil Separator, Showa Lubricator, Mist Collector, S/N 132 VIEW LOT #51

- Mori Seiki MV-40E CNC Vertical Machining Center, MSC-500 CNC Control, Travels: 22.04”, Y-16.14”, Z-18.11”, With 35” x 17.71” Table, 660 Lb. Table Load, 20 ATC, 60-6000 RPM, 40-Taper Spindle, Nikken CNC 180 Rotary Indexing Table, Coolant, Oil Separator, Showa Lubricator, Mist Collector, S/N 1243 [2000] AN #BT6060 VIEW LOT #61

- Brother TC-321 CNC Drilling & Tapping Center, Travels: X-27.55”, Y-11.81”, Z-9.84”, with 31.49” x 11.81” Table, 10-Position Tool Turret, 6-6000 RPM, BT-30 Taper Spindle, Brother CNC Control, S/N 112126. AN# BT4191 VIEW LOT #85

- Bridgeport VMC-3020XV CNC Vertical Machining Center, Fanuc 21i-M CNC Controls, Travels: X-30″, Y-20″, Z-20″, with 36” x 18” Table, 10-10,000 RPM, 20-Station Automatic Tool Changer, CAT 40 Taper, Renishaw OMM Optical Module Machine, Coolant, AN# BT6037 VIEW LOT #9

SPLINE ROLLERS:

- Anderson Cook 350 Spline Roller, 56″ Stroke, 48″ Max Rack Length, 4.75” Max. Rack Face Width, 2.5” Max Part Dia., 30”/44″ Max Part Length, Live Center Headstock and Tailstock, 40 HP, Coolant, S/N 261, [1991] VIEW LOT #163

- Micromatic Textron Rotoflow Systems 3251 Spline Roller, 48″ Max. Rack Length, 3″ Max. Part Dia., Servo Controlled Headstock and Tailstock, 40 HP, Coolant, Allen Bradley PanelView 600, S/N 400159 VIEW LOT #164

BORING & DRILLING CENTERS:

- Drillmaster 3-Axis Vertical Face, Center Drill and Boring Machining Center, 20 HP Upper Spindle Drive, 5 HP Lower Spindle Drive, Part Detection, ID, and Datum Sensors, Air Chuck, Swing Cylinder Clamps, Spring Loaded Jaws, Allen Bradley PanelView 1000 Interface, SLC-503 PLCs, Keyence Light Curtains, Chip Conveyor, Mist Collector, S/N 8425-0, AN# BT5716

- Drillmaster 6-Station Vertical Boring Machine, Equipped with (1) Part Loading/Unloading Station, (1) Probing Station, (2) Boring Stations, (2) Gaging Stations, Edmunds Gaging, Allen Bradley PanelView 1000, Light Curtains, SKF Auto Lubricators, (2) Koolant Koolers HCV 1500-PR Oil Chillers, 10 HP and 5HP Hydraulic Pumps, Aget Dustkop Cyclone Dust Collector, Aget FT40-D1-SP Bag House Dust Collector, S/N 8430-0, AN# BT5824

HONES:

- Sunnen KGM-5000NTE-S3 CNC Horizontal Hone, 5.90” Max. Work Dia., 4.4 Lb. Max. Work Weight, 3700 RPM Max. Spindle Speed, 33-500 SPM, Coolant Filtration, Magnetic Separator, S/N 4D1-1055 [2006]

- Sunnen DMS3-30 Vertical CNC Bore Sizer Hone, 3-Spindles, 2-Columns, 6″ x 6″ x 6″ Max. Part Size, 0.233″-2.055″ ID Range, 1-100 IPM Stroke, 1-600 RPM Spindle Speed, 36” 12-Position Rotary Indexer, 5 HP and 3 HP Spindle Drives, Allen Bradley PanelView Plus 700, Coolant Filtration, AN# BT3907 VIEW LOT #125

- Gehring Micromatic ZH-600-125 4-Spindle 8-Station Cylinder Bore Honing Machine, with (1) Part Loading/Unloading Station, (1) Part Type ID Station, (1) Type 883 Microsize Machining Station, (1) Type 883 Honing Station, (1) Type 1200 Microsize Machining Station, (1) Type 1200 Honing Station, (1) Post Gauge QC Station, Rotary Indexing Parts Table, (1) Part Marking Station, Xycom Operator Interface, Hydraulic Power Unit, Mist Collector, SKF Auto Lubricator, S/N GC260 [2001] AN# BT5742

- Universal Automatic / Engis Model 9825 16S 6-Spindle Vertical Hone, Single Column, 32” 10-Position 32″ Rotary Table, Trabon Lube, Encyclone Cyclonic Coolant Filtration System, PLC Control Panel, Allen Bradley PanelView Plus, S/N 98086. AN# BT5472 VIEW LOT #202

- Accu-Cut Diamond Tool 2X1SMCRIG 3-Station Vertical Bore Sizing Hone, (1) Unload/Loading Station, (1) Vertical Roughing Honing Station with Reciprocating and Expanding Tool Assembly Spindle Head, (1) Vertical Finishing Honing Station with Reciprocating and Expanding Tool Assembly Spindle Head, Rotary Parts Indexing Table, Barnes Fabric Filtration Unit, S/N BSM258 [1999] AN# BT5435 VIEW LOT #32

GRINDING MACHINES:

- Mattison Machine Works Type 100C 5-Spindle Rotary Surface Grinder, (5) 40 HP Spindle Drives, Automatic Sizer, Wheel Dresser, Rotary Parts Table, Torit Dryflo Mist Collector, Oberlin OPF Coolant Tank, 10HP Coolant Pump, 15HP Sump Pump, Auto Lubricator, S/N 100C-56. AN# BT3102 VIEW LOT #177

- USACH TST Tripet 250 CNC Internal Grinder, GE Fanuc Series 16-T CNC Control, 15.7” I.D./ 7.87” O.D. Grinding Capacity, 9.84”Grinding Length, 10.23” Center Height, 220 Lb. Max. Workpiece, MK5 Spindle Taper, 45-15,00RPM Workhead Speed, 13.77” Workhead Axial Adjustment, Travels: X-9.84”, Z-27.55” -15/+35 Degree B-Axis Tilt Range, 42,000 RPM GMM HSX 150-42000/11 Grinding Spindle, Diamond Wheel Dresser, Nordmann SEM-68000 Tool Monitor System, Mist Collector, Coolant, Filtration, S/N T2502514 [1998] AN# BT5294 VIEW LOT #180

- Bryant UltraLine UL2 High Speed CNC Grinder, 7″ Max Swing, 4/5.5″ Max Bore, 3″ Max Bore Length, Travels: X-2.36”, Z-10”, Feedrates: X-520 IPM, Z-1800 IPM, 0.4 Micron Z-Axis resolution, 0.1Micron X-Resolution, 120,000 RPM Max Spindle Speed, Wheel Dresser, Auto Size Control, Allen Bradley PanelView 1400E, Parts Conveyor, Mist Collector, Oberlin OPF Tank, S/N 17658. [1994] AN# BT4553 VIEW LOT #86

COORDINATE MEASURING MACHINE:

- Sheffield Discovery II D-28 CMM, 32″ x 42″ Granite Surface Plate, Renishaw PH10T Probe, SCR200 6-Station QC Probe Rack, PT200 Probe Interface Unit, PHC 10-2 Probe Head Controller, Remote Control Pendant, Operator Computer Station. S/N S-0621-0106. AN# BT6948 VIEW LOT #86

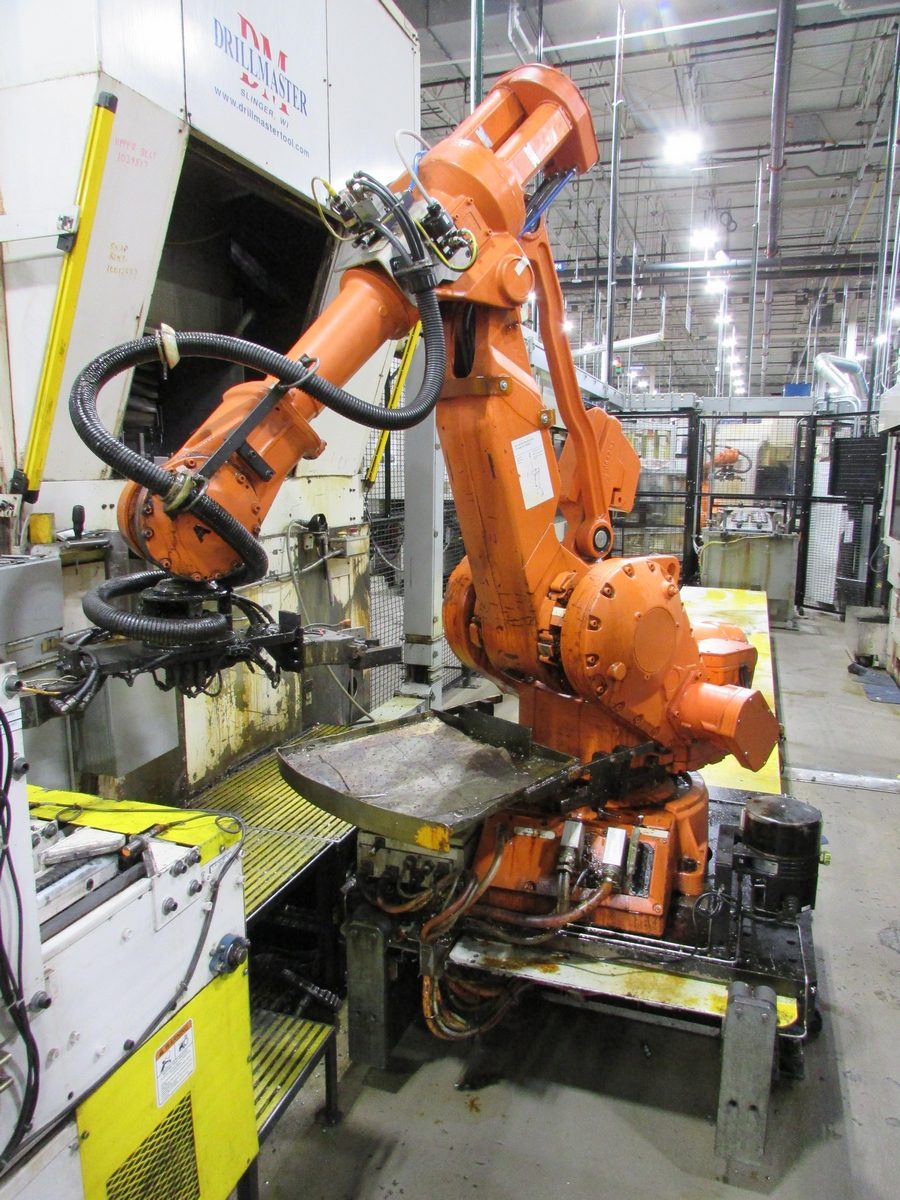

ROBOTS:

- (2) ABB 4400L 2.43-30 6-Axis Robots, S4CPLUS M2000 Control, TPU2 Teach Pendant, S/N 44-27376 [2004] & 4427375 [2004] LOT 161, AN# BT6568; LOT 1 AN# BT6567 VIEW LOT #161 / VIEW LOT #1

- ABB IRB 4400/60-1.95 6-Axis Robot, IRC5-M2004 Control Cabinet, DSQC 679 Teach Pendant. S/N 44-52739, [2008] AN# BT7264 VIEW LOT #63

- ABB IRB 4400/45 M99 6-Axis Robot, 24″ Pedestal, SR4C Control Cabinet and Teach Pendant, S/N 44-15385 [2000] AN# BT5774 VIEW LOT #149

- ABB IRB 4400/1.95-45 6 Axis Robot, S-4C Control, Teach Pendant, Approx 23′ ABB Servo Track, Lincoln Automatic Lube, S/N 44-15625 AN# BT5899 VIEW LOT #59

- ABB IRB 4400/1.95-45 M99 6-Axis Robot, 18″ Pedestal, S4C Control, Teach Pendant, S/N 44-15389. AN# BT5772 VIEW LOT #139

- ABB IRB 4400/1.95-60 M98A 6-Axis Robot, 20″ Pedestal, S/N 44-12564 [2004], S4C Plus M2000 Control, Teach Pendant, S/N 44-26920. [1999] BT6405 VIEW LOT #145

- ABB IRB 4400/1.95-45 M99 6-Axis Robot, 18″ Pedestal, S4C Control, Teach Pendant. AN# BT5882 VIEW LOT #141

- ABB IRB 3000/S3 M93A 6-Axis Robot, 18″ Pedestal, Control Cabinet, IRB6000 Teach Pendant. S/N IRB3000-1535. AN# BT-3972 VIEW LOT #126

- (2) ABB IRB 1400/1.44-5 6-Axis Robot, 24″ Pedestal, S-4C Control, Teach Pendant. LOT 90, AN# BT574; LOT 91, AN# BT5890 VIEW LOT #90 / VIEW LOT #91

- ABB IRB 140 Type B M2000 6-Axis Robot, 40″ Pedestal, S4C Plus M2000 Control Unit with Teach Pendant. S/N 14M-27242. [2005] AN# BT6716 VIEW LOT #146

PRESSES:

- (2) Neff 12.44 Ton Hydraulic Gap Frame Presses, 7.5” Throat, 7″ Stroke, 14.5″ x 10.5″ Base, Promess PPM Press Force Monitor, Allen Bradley PanelView 600, PLC Control Cabinet, 5HP Hydraulic Power Unit, Mounted to 30″ x 30″ Steel Workbench. S/N 11604 [2001] AN# BT5999; AN# BT4559 VIEW LOT #179 / VIEW LOT #182

- Neff D12-5M 12.44-Ton 4-Post Hydraulic Press, 18″ Max Daylight, 7″ Throat, 7″ Stroke, 35″ x 15″ Between Posts, 24″ x 44″ Platen, 3000 Max. PSI, S/N 10672 [1999] – AN# BT4550, VIEW LOT #31

- Neff 12.4 Ton Hydraulic Gap Frame Press, 7″ Stroke, 7″ Throat, 10″x14″ Platen, 3,000 Max PSI, Allen Bradley PanelView Plus 700 Interface, S/N 10714 [1997] AN# BT4560 VIEW LOT #53

- Hannifin OGF20-12-2-2-SPC 20 Ton Hydraulic Gap Frame Press, 14″ Throat, 24″ x 21″ Platen, 2040 Max PSI, S/N T-13275. AN# BT2956 VIEW LOT #81

- Hess-MAE HY-S040-RH 40 Ton RH Hydraulic Straightening Press, 8″ Stroke, 10″ Throat, 55″ x 11″ Bed, Parts Carriage, Parts Anvil, Head and Tailstock, Quartech 9800 Operator Interface Terminal, Model 2100 Straightening Control, Electronic Stroke Control, S/N 255 [1996] AN# BT5490 VIEW LOT #54

- Tox Pressotechnik MC-9 9-Ton Pneumatic Marking Press, 6″ Throat, 7.5″ x 12″ Table, 1.97″ Total Stroke, 0.47″ Power Stroke, Electronic Control, Mounted to 4′ x 2′ Steel Work Bench. S/N 089 90 911, [2005] AN# BT6570 VIEW LOT #93

- Schmidt Pneumatic Hydraulic Bushing Press, 16″ x 15.5” Bottom Platen, 8″ x 10″ Top Platen, Load Cell Sensors, STI MiniSafe Light Curtains, Parker CTC Interface, Allen Bradley SLC5 PLCs, Mounted to 40″ x 34″ Steel Work Bench, AN# BT5930 VIEW LOT #117

- Midwest Engineering Systems Vertical 3-Post Hydraulic Bearing Press, 32″ x 24″ Platen, 10″ Throat, 23″ x 19″ Between Columns, Miller Fluid Power Hydraulic Cylinder, 3000 Max PSI, 10 HP, Promess Press Force Monitoring System, Allen Bradley PanelView 600, S/N 4856, AN# BT3414 VIEW LOT #50

- Midwest Engineering 17-Ton PLC Controlled Hydraulic Gap Frame Race Press with Thrust Washer Control System, Approx 9″ Stroke, 10″ Throat, Parts Shuttle, Gravity Hardware Feeder, Shuttle Unit, Promess PPM Assembly Monitoring System, Allen Bradley PanelView 600, S/N 46051. AN# BT6024 VIEW LOT #60

- Universal Automatic Machine Bushing Press Machine, (2) Vertical Hydraulic Cylinders, Hydradyne 5 HP Hydraulic Power Unit, (2) Promess PPM Press Force Monitors, (2) Vibratory Bowl Hardware Feeders, PLC Control Panel with Allen Bradley PanelView Plus, S/N 98086. AN# BT5470 VIEW LOT #200

- Universal Automatic Machine AM020 Bushing Press Machine, Equipped with (2) Vertical EMAP Electro Servo Cylinders, (2) Midwest Feeder Vibratory Bowl Hardware Feeders, PLC Control Panel with Allen Bradley PanelView Plus Interface, 480V 60Hz 3PH. S/N 98086. AN# BT5471 VIEW LOT #201

- (2) Hannifin B-16 Pneumatic Arbor Press, 6″ Throat, Push Button Pneumatic Valve Actuator, Mounted to 28″ x 33″ Steel Workbench. AN# BT2060 & AN# BT1824 VIEW LOT #80 / VIEW LOT #175

- Shop Built Pneumatic Hydraulic Dowel Pin Press, Equipped with (2) Enerpac RW53 5-Ton Hydraulic Cylinders, Enerpac B3304 Hydraulic Unit – AN# BT3773 VIEW LOT #30

- Shop-Built Pneumatic Hydraulic Dowel Pin Press, Equipped with Enerpac RW104 10-Ton Cylinder, AN# BT4126 VIEW LOT #2

- Shop-Built Hydraulic Dowel Pin Insertion Press, (2) Hydraulic Cylinders, Hydraulic Power Unit, Vibra-Flight Vibratory Bowl Feeder, Feed Rate Controller, AB PanelView 300 Micro Interface, AN# BT6232 VIEW LOT #33

- Shop-Built Assembly Station with Insertion Press, (2) Vibra-Flight Vibratory Bowl Feeders, 3-Axis Pick & Place Robot, Pneumatic Hydraulic Unit, Pneumatic Actuated Torque Driver, Tool Balancer, Telesis TMM5100 Pinstamper with Controller, Keyence Light Curtains, Allen Bradley PanelView 600 Interface – AN# BT6233 VIEW LOT #34

PARTS WASHERS & VIBRATORY FINISHERS:

- CAE Ransohoff Dual Station Parts Washer, Pneumatic Doors, Approx 28″x16″ Doorway, (2) 8″ x 6″ Motorized Parts Rotators Per Wash Station, Wash and Blow Off, Keyence Light Curtains, Exhaust Fan, (2) 20 HP Gusher Pump, (4) Bag Filtration, Watlow Electric Tank Heaters, 3 HP Sump Pump, PLC Control Panel, Allen Bradley PanelView 600, S/N 4027, [2001] AN# BT6063 VIEW LOT #160

- CAE Ransohoff 4066 3-Stage Automatic Conveyor Parts Washer, 80 Pallets Per Hour, 0.5-5 FPM, 2060 Chain Conveyor Type, 13″ x 10″ Window, Wash Station, 400 Gal. Tank, Watlow 100W Electric Tank Heater, 160F Wash Temp, Quickjet Spray Nozzles, Gusher Pumps, 210 Gal. Tank Rinse Station, Watlow 100W Electric Tank Heater, 140F Rinse Temp, Exhaust Fan, Hot Air Blow-Off Station, Partlow Temperature Controllers, Mayfran Oil Decant Tank with 7.5HP Pump, (2) LPH6SAPTC3XXX Dosing Pumps, (2) Pulsatrol Series 100 Controls, DiaLog DACb ProMinet Control, Dual Bag Filter Cannisters, Allen Bradley PanelView 600, S/N 4066, [2001] AN# BT6059 VIEW LOT #11

- ADF Systems 8044-032-011-R Heated Parts Washer, Equipped with 32″ Dia. Rotary Wash Basket, Electric Heated Wash & Rinse Tank, Wash & Rinse Timers, Goulds SSV 2HP Pump, S/N 9605-3011, AN# BT4356 VIEW LOT #14

- ADF Systems 800 Rotary Heated Parts Washer, 32″ Dia. x 5″ Wash Basket, Wash & Rinse Tanks with Electric Tank Heaters, Oil Separator, Wash, Rinse and Drying Timers, S/N 9505-2668., AN# BT4233 VIEW LOT #115

- Automated Finishing 4078 Automatic Conveyor Parts Washer, 11″ Conveyor Width, Approx 14″ x 8″ Parts Window, Wash & Blow-Off, Wash Tank, Watlow Electric Tank Heaters, Bag Filtration, Oil Separator, 5 HP Gusher Pump, Sump Pump, Milton Roy Dosing Pump, Donaldson Torit Mist Collector, 8″ Part Discharge Belt Conveyor, PLC Control, Allen Bradley PanelView Plus 600, AN# BT5488 VIEW LOT #203

- Automated Finishing 3905 Parts Washer, 25″x15″ Parts Tray Loader, 30″ x 18″ Pneumatic Door, STI Light Curtains, Wash Tank, Watlow Electric Tank Heaters, Milton Roy Dosing Pump, 3HP Gusher Pump, Bag Filtration, Mist Collector, Sump Pump, PLC Control, Allen Bradley PanelView 600, AN# BT4287 VIEW LOT #178

- Automated Finishing Automatic Parts Washer, 12″ SS Belt Parts Conveyor, 12″ x 8″ Parts Window, 182 Gallon Wash Reservoir Tank, Filter Cartridge, (2) Watlow 7.5 KW Electric Tank Heaters, Watlow EZ-Zone Temp Control, 3 HP Wash Pump, Discharge Pump, Milton Roy Dosing Pump, Air Dryer Blower, Torit Dryflo Mist Collector, AN# BT5567 VIEW LOT #3

- Automated Finishing 2V5 Vibratory Finisher, 36″ x 12″ x 16″ 4-Section Vibratory Chamber, Pneumatic Door, Omron H5CX Process Timer, Oberlin OPF Tank, AN# BT5337 VIEW LOT #181

FILTRATION SYSTEMS:

- Oberlin Pressure Filter OPF-18 Pressure Filtration System, 18 Sq. Ft. Cap., 52″ Filter Media, Dirty and Clean Tanks, ARO Pneumatic Diaphragm Transfer Pumps, (3) 20HP Gorman 80 Series Centrifugal Pumps, Tank Agitator, Plate Type Heat Exchanger, Torit Dryflo Mist Collector, PLC Control, Allen Bradley PanelView 600, S/N 031SD [2002] AN# BT6177 VIEW LOT #183

- Oberlin OPF-07 32″ Pressure Filtration System, 7 Sq. Ft. Filtering Area, 7.5 HP Gusher Clean Pump, 10 HP Gusher Filter Pump, Allen Bradley PanelView 550, S/N 430SD, AN# BT6071 VIEW LOT #13

TESTING EQUIPMENT:

- Cincinnati Test System 2-Station Mass Flow Leak Testing Machine, (3) Cincinnati Test Systems F-21 Mass Flow Instrument Controls, (2) Load/Unload Stations, Linear Parts Shuttles, Parker Pneumatic Cylinders, HMI Unit, Allen Bradley SLC5/05 PLCs, CTS Talk PLC Program, S/N 1621, AN# BT6070 VIEW LOT #35

- (2) Cincinnati Test System 1-Station Mass Flow Leak Testing Machine, (2) Cincinnati Test Systems F-21 Mass Flow Instrument Controls, Load/Unload Station, Linear Parts Shuttle, Parker Pneumatic Cylinders, HMI Unit, Allen Bradley SLC5/05 PLCs, CTS Talk PLC Program, S/N 1696. LOT 36, AN# BT6263 & LOT 37, AN# BT6264 VIEW LOT #36 / VIEW LOT #37

- Phase One Instruments Single Station Gear Cover Part Leak Test System, (11) Bimba Stainless Pneumatic Cylinders, STI MiniSafe-B Light Curtains Allen Bradley PanelView 550 and Allen Bradley PLC Controls, AN# BT5279 VIEW LOT #116

- Phase One Instruments Crank Pin Flow and Leak Testing System, 10 PSI and 3 PSI Leak and Flow Testing Pressures, STI Minisafe-B Light Curtains, Allen Bradley PanelView 550, Small Compressed Air Storage Tank, AN# BT5524 VIEW LOT #55

- Hommel America QA Parts Checking Station, with Mitutoyo SJ-310 Probing Station, 3″-3.5″ Measurement Probe, AN# BT5881

- Hommel-Etamic Parts Gaging System, CMZ200 Interface, VIEW LOT #102

MISCELLANEOUS EQUIPMENT:

- Acro Automation System Fly-Wheel Connecting Rod Assembly Machine, 5-Station Shuttle Transfer Assembly Line, 36”-40″ Loading Height, 18″ Tailstock Press Stroke, 20-24″ Head To Tailstock, 19″ Main Shuttle Transfer Stroke, Station 1: Automatically Presses Flywheel with Auto Leak Test, Part Orientation Detection System and Unload Mechanism, Station 2: Idle, Station 3: Locates Assembly and Auto Drives Crank Pin Nuts with Auto Unload Mechanism, Station 4: Idle, Station 5: Unloading Assembly, Equipped with Promess PPM Press Force Monitoring System, STI Minisafe Light Curtains, Antares DRO, HMI, Allen Bradley SLC5/03 PLCs, S/N 1588, AN# BT4382 VIEW LOT #52

- Ingersoll Rand 720 150Lb. Free-Standing Articulating Jib Crane, with Approx 8′ Post, 8′ Articulating Arm, Ingersoll Rand Zimmerman 150 Lb. Cap Pneumatic Tool Balancer and Pneumatic Actuated Lifting Hook Attachment, AN# BT7438 VIEW LOT #64

ASSEMBLY STATIONS, HANDLING SYSTEMS, AND CONVEYORS:

- Denso Overhead Gantry Mounted Robot with Dual Parts Gripper, TP-RC7/8 Teach Pendant, Overhead Gantry Tray Handler, Telesis Merlin II LS Laser Marking System, BSI Interface, Twin Tray Elevator Stations, Parts Sample Drawer, S/N 2337 [2008] AN# BT7236 VIEW LOT #100

- (2) Distech Systems DS1100 Automatic Robotic Parts and Tray Handling System, Denso VS-6577GM-BW Overhead Gantry Mounted Robot, Parts Gripper, TP-RC7/8 Teach Pendant, Parker CTC Interface, Twin Tray Stations, Parts Sample Drawer, S/N 2335 & S/N 2334 [2008] AN# BT7235; AN# BT7234 VIEW LOT #98 / VIEW LOT #99

- Distech Systems DS1200 Automatic Robotic Parts and Tray Handling System, Denso Overhead Gantry Mounted Robot, Dual Parts Gripper, TP-RC7/8 Teach Pendant, Overhead Gantry Tray Handler, Telesis Merlin II LS Laser Marking System, BSI Interface, Twin Tray Elevator Stations, Parts Sample Drawer, S/N 2336 [2008] AN# BT7238 VIEW LOT #101

- Westech Tech-Trak Pallet Conveyor System for Ransohoff Parts Washer, Approx 775″ Total Conveyor Length in L-Shaped Configuration, PLC Controlled Conveyor Loop with Asynchronous Pallet Transfer Unit, (1) Load/Unload Station, Drip Trays, S/N 3500, [2001] AN# BT6094

- H&CS Dual Lane Silent Chain Parts Conveyor, 8″ Lane Width, 20″ Total Width, 10′ Length, Pneumatic Parts Stops, PLC Control Cabinet with Allen Bradley PanelView 550 Interface. AN# BT7475/ CONV-1 VIEW LOT #65

- Dornier 2200 Series 5″x42″ Parts Reject Conveyor, with 45″ 2-Part SPC Linear Shuttle with Banner Sensors. [2005], AN# BT6749 VIEW LOT #96

- H&CS 19″W x 10’L Over/Under Pallet Conveyor, Top Pallet Accumulation Conveyor, Bottom Pallet Return Conveyor with (2) 19″x16″ Conveyor Elevators. PLC Control Cabinet, Allen Bradley PanelView 550 Interface, VIEW LOT #66

- Hytrol PLC Controller 19.5″ Powered Roller Conveyor System, (1) Approx. 21′ x 19.5” Roller Conveyor Section with Proximity Sensors and Parts Stops, (1) Approx. 24 ‘x19.5″ Roller Conveyor Section with Proximity Sensors and Parts Stops, Roller Chain Transfer Conveyor, PLC Control, Allen Bradley PanelView 550 VIEW LOT #105

- (3) ABB IRBM 1000 24″ x 19″ Pallet Magazine Systems, S/N’s 5014434K-001 [2000], 5014434K-007 [2000], 6796 0004-024 VIEW LOT #127 / VIEW LOT #138 / VIEW LOT #142

- Turn-Key Solutions 4-Lane Plastic Link-Belt Accumulation Conveyor, Approx. 3-1/2″x54″ Conveyor Lanes, 18″ Total Conveyor Width, Allen Bradley PanelView 300, S/N TKS0834 [2008]. AN# BT7243 VIEW LOT #147